Safely and Efficiently Mix Liquids with the SAFECHEM Mixing Tank

Mixing liquids with varying viscosities presents challenges in both process safety and efficiency. The SAFECHEM Mixing Tank is designed to provide safe, rapid mixing for industrial applications. Its innovative features enable fast dissolution and dispersion without product loss.

Safety is the top priority with the SAFECHEM Mixing Tank. It has a hinged closed hood and sight glass to contain liquids and powders. Bags are placed on a conveyor and slit open via a star slitter or pneumatic slitter to prevent spills. The enclosed design contains dust and fumes for a cleaner, safer process.

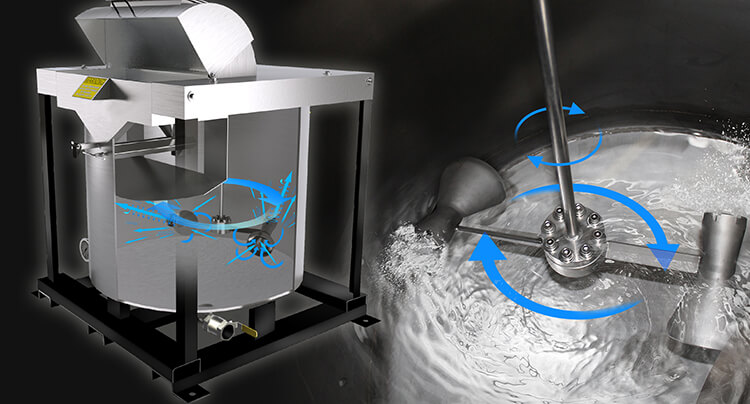

At the heart of the SAFECHEM Mixing Tank is the Conical Induction Agitator. Driven by air or an electric motor, it generates a powerful vacuum that rapidly draws in and mixes liquids. The conical elements thoroughly blend viscous liquids and dissolve powders through an energy-efficient Venturi effect.

Key benefits of the Conical Induction Agitator include rapid dissolution of polymers and caustics, emulsification of liquids, and suspension of solids. It requires less horsepower than conventional mixers, saving energy. The SAFECHEM Mixing Tank allows efficient, uniform mixing in a safely enclosed system.

The SAFECHEM Mixing Tank delivers safety and performance for industrial mixing applications. Its enclosed design and bag slitting system prevent spills and emissions. The Conical Induction Agitator mixes efficiently even with high-viscosity liquids. For safe, powerful mixing of liquids and powders, the SAFECHEM Mixing Tank is an ideal solution. Contact us to learn more or request a quote.